Sati Italia’s metal trunking systems are a benchmark in the industry, exemplifying the excellence of Made in Italy. Our facilities boast state-of-the-art processing technology, a certified hot-dip galvanizing department and an environmentally friendly powder coating plant located close to the production lines. These elements, combined with an efficient logistics service and attentive, precise customer care, contribute to our success.

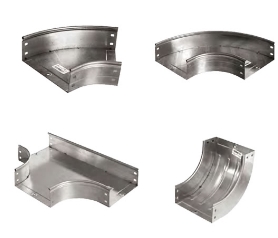

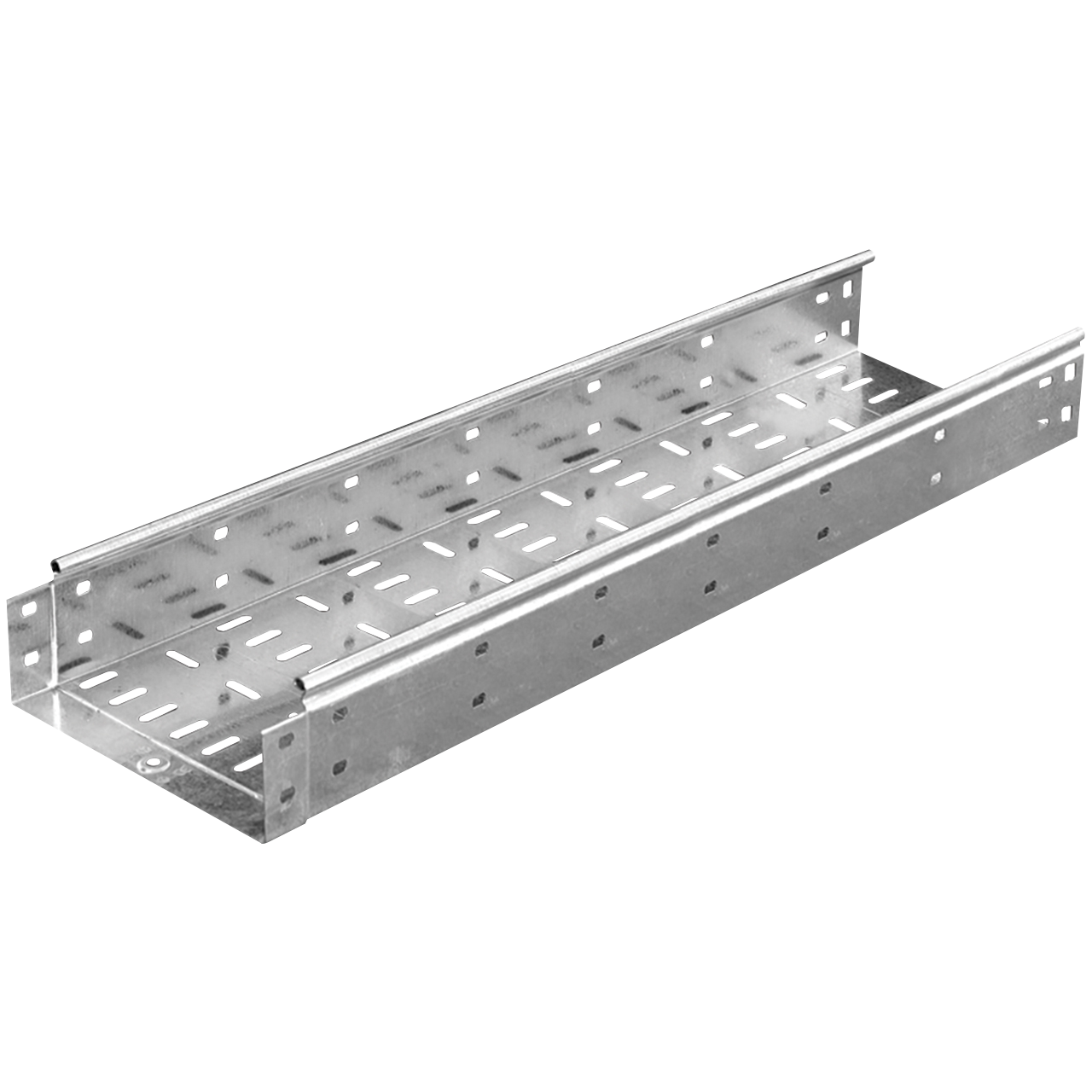

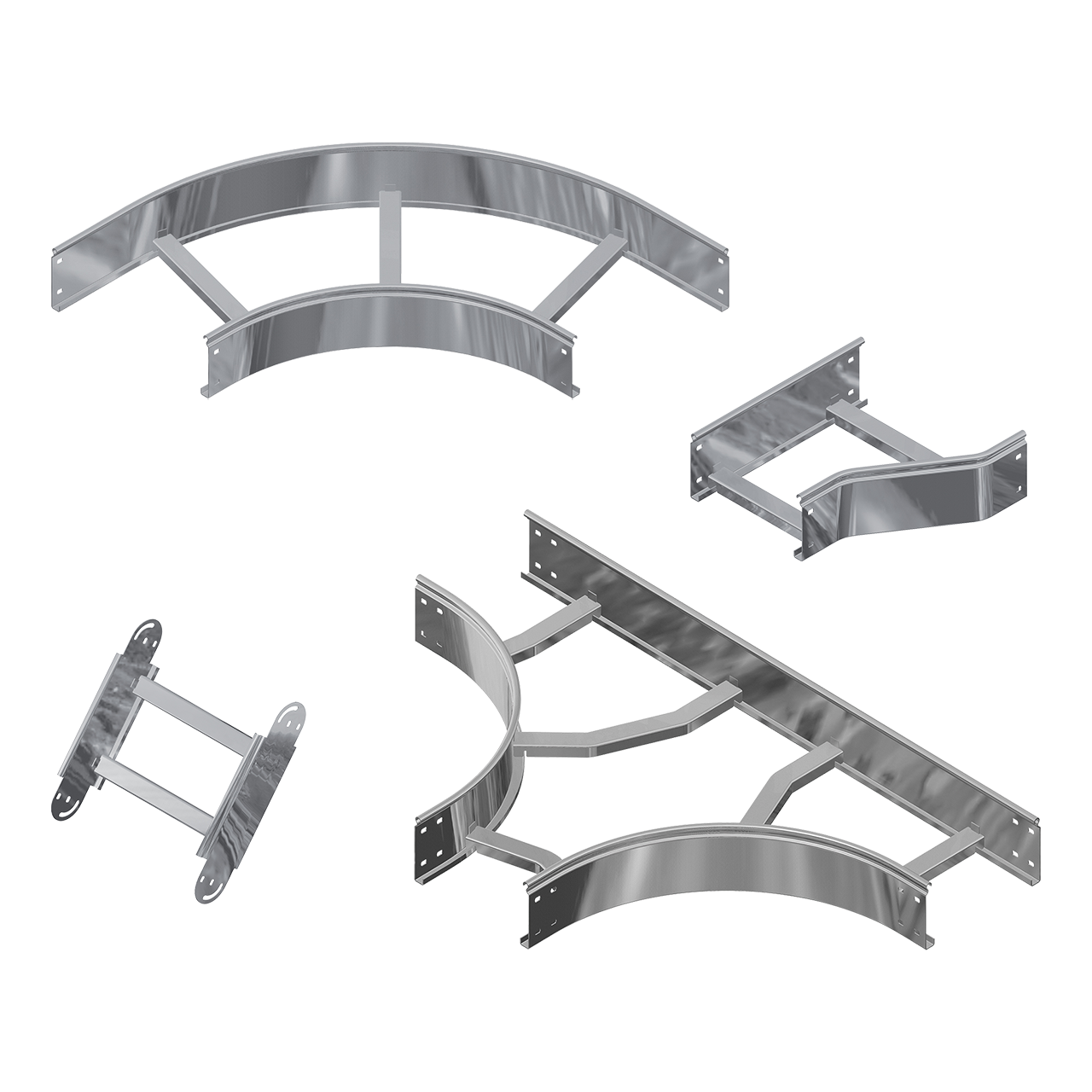

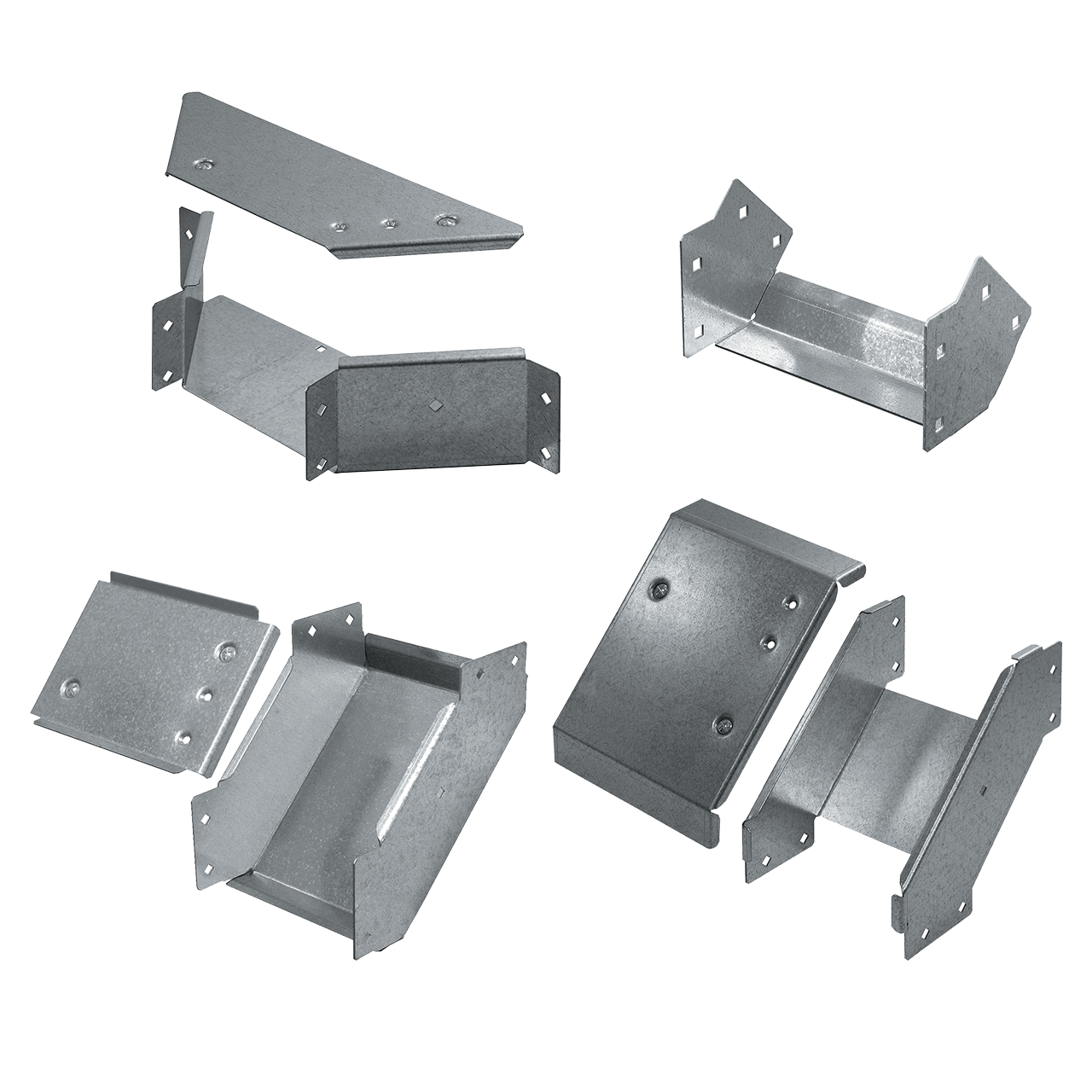

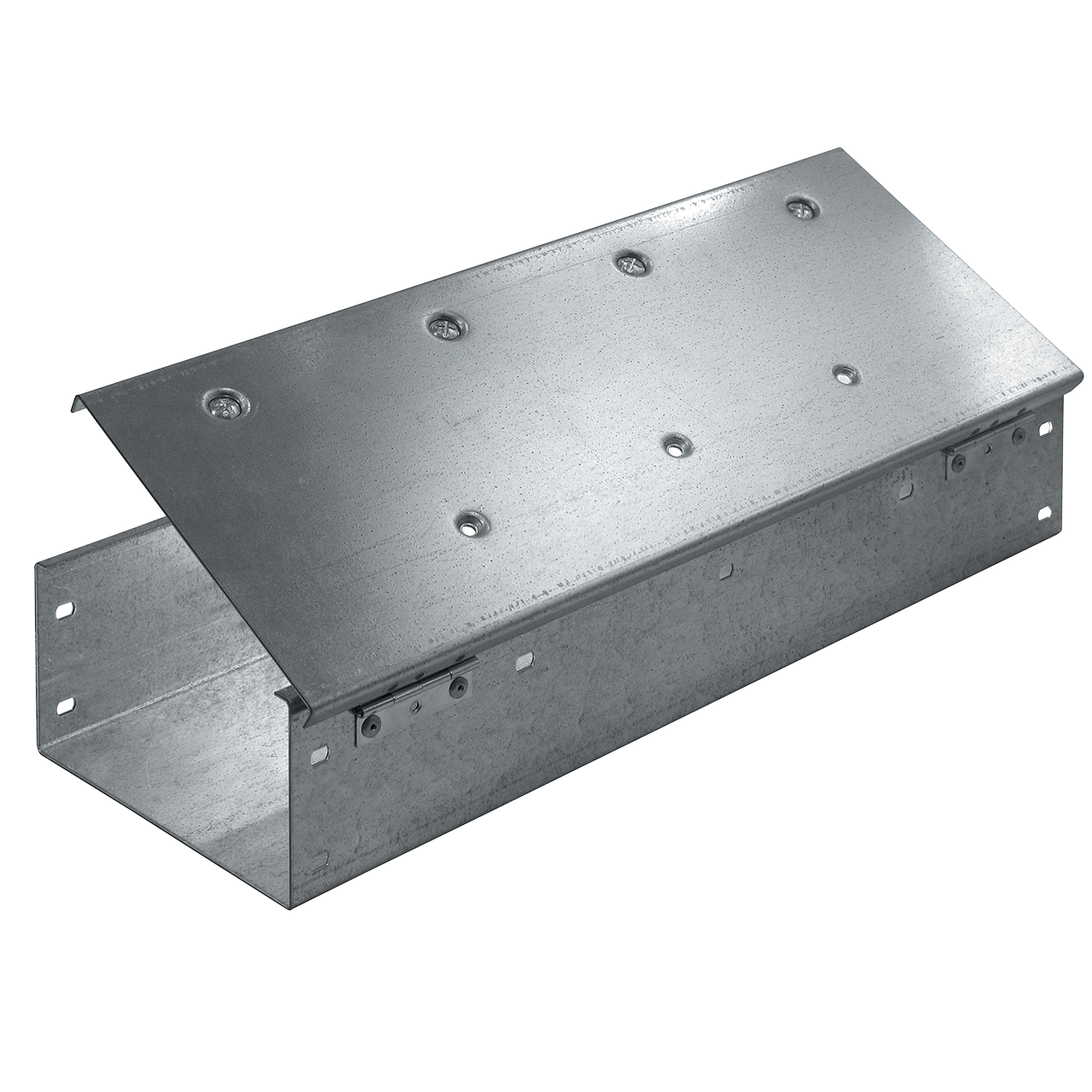

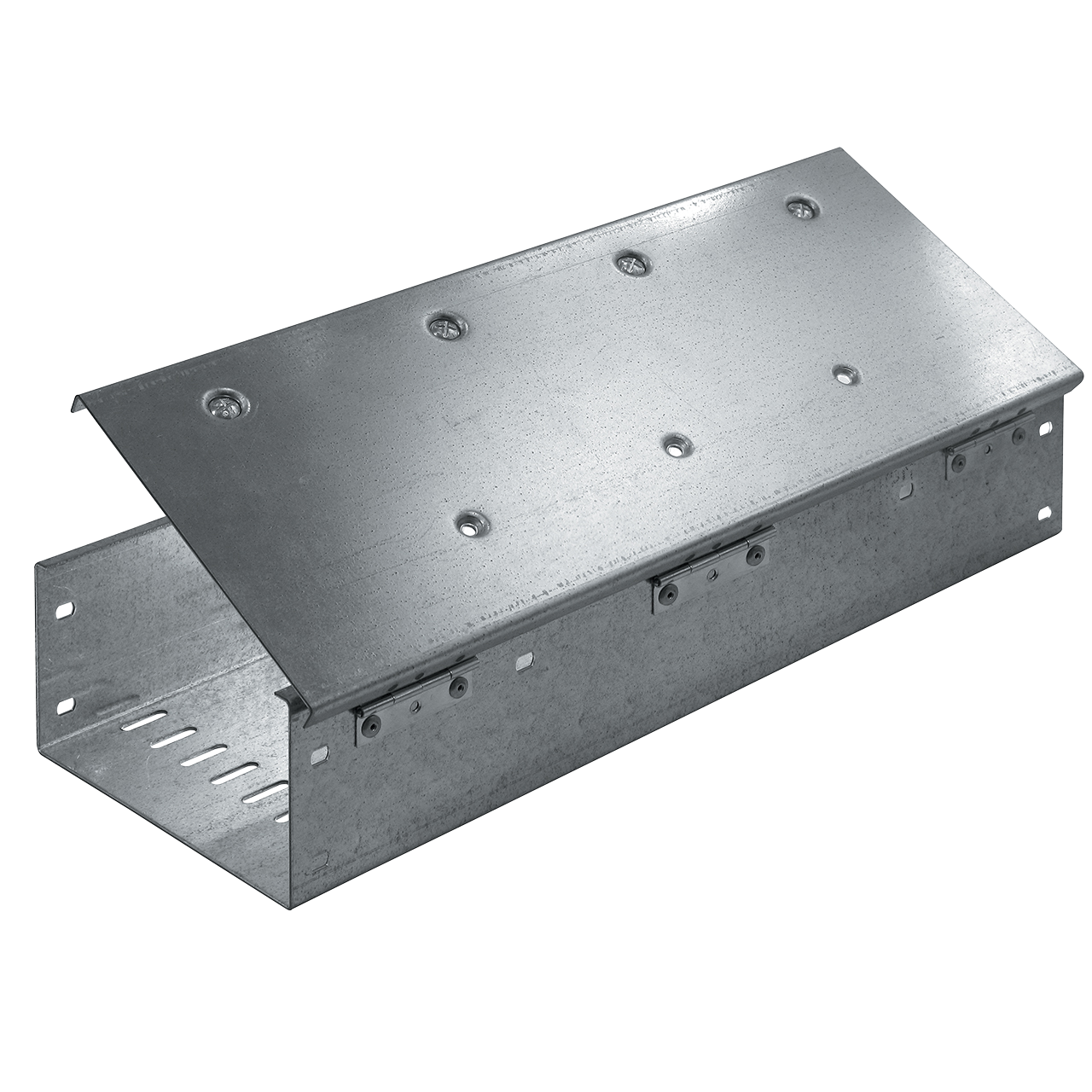

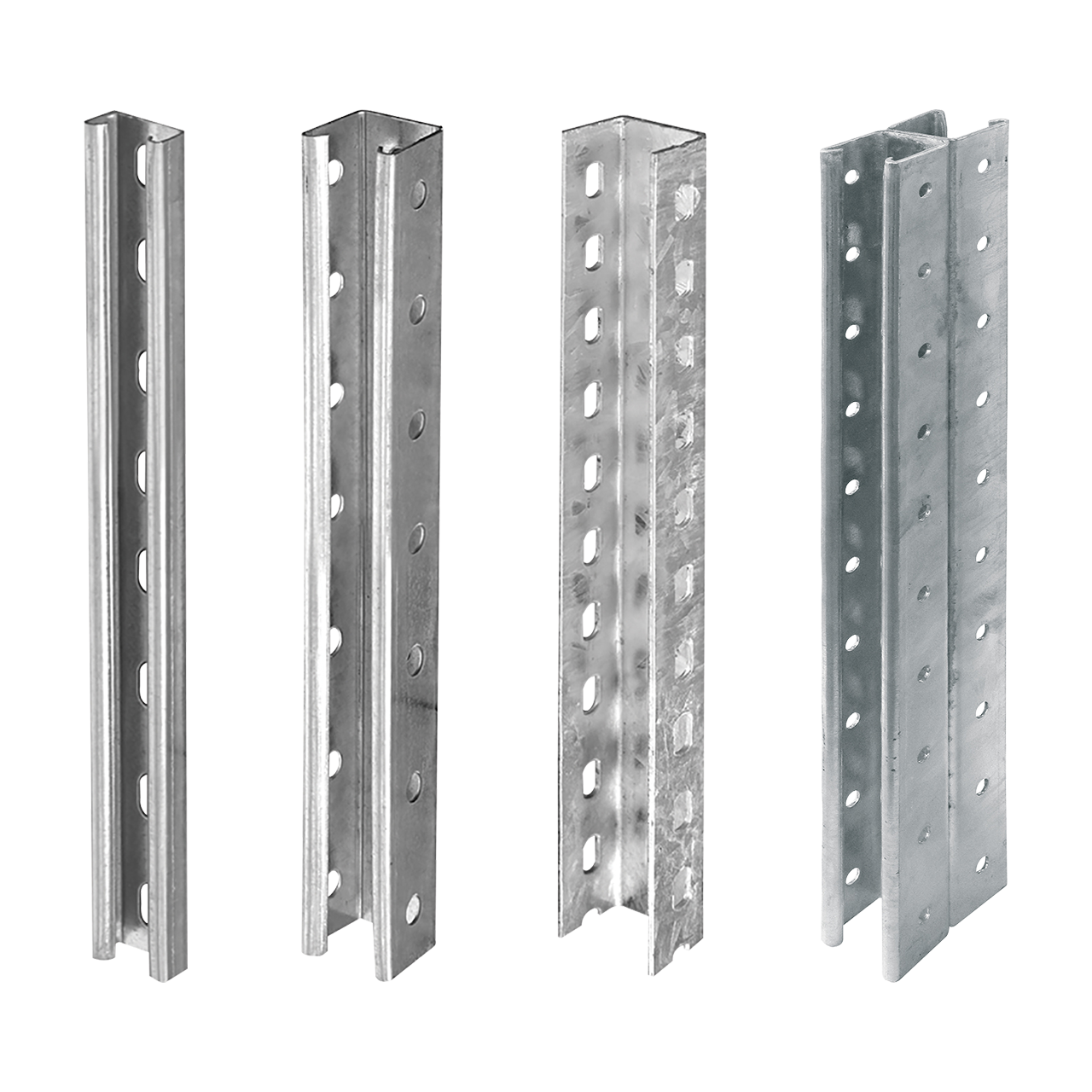

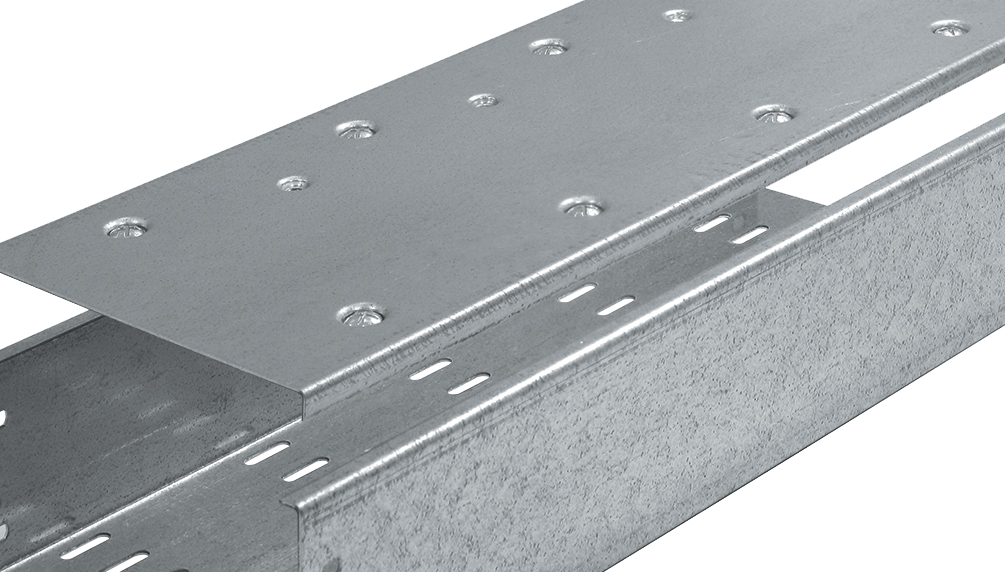

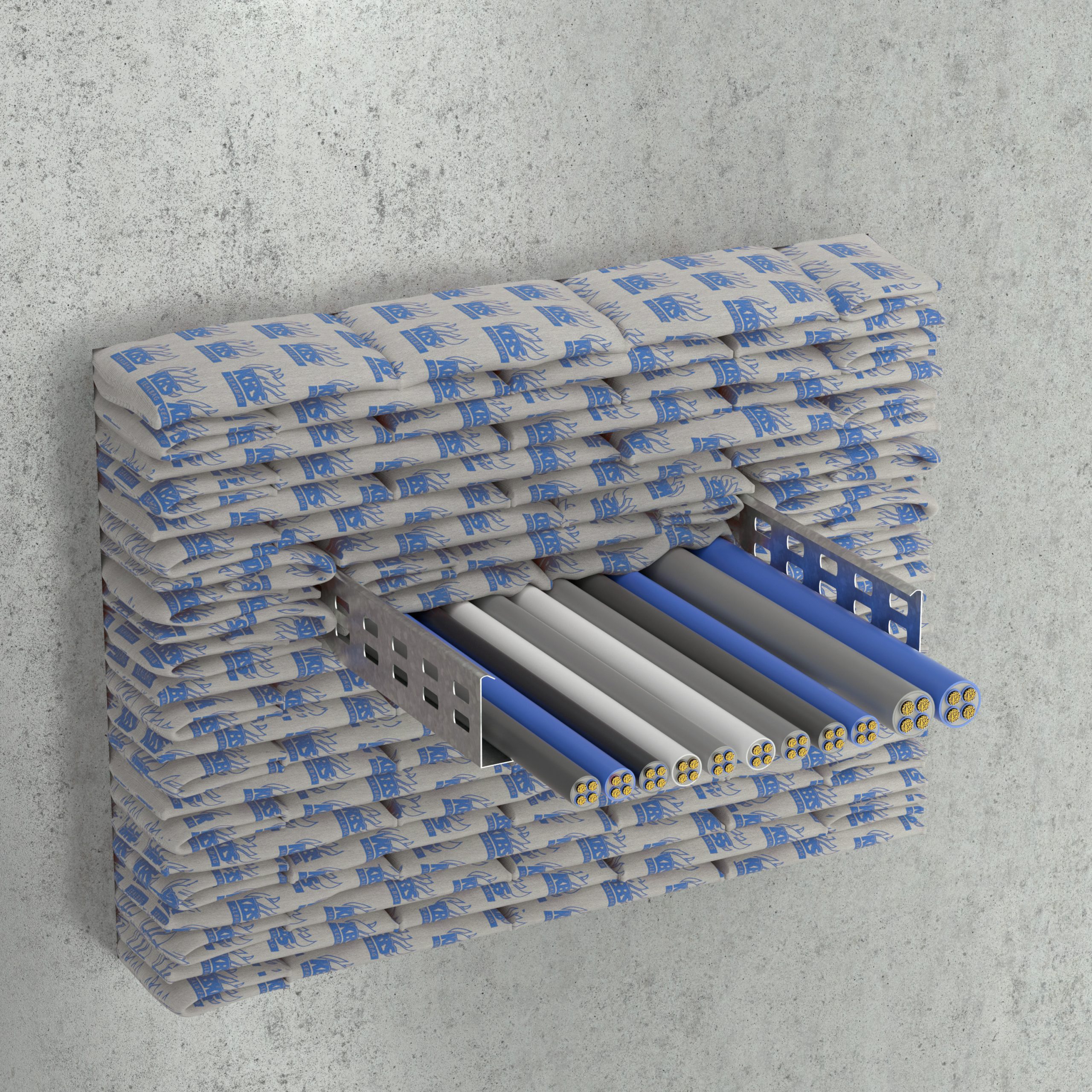

The Line S5 trunking system is considered Sati Italia’s core business product. The Line is characterised by the special geometry of the straight element, a feature that differentiates it from other products on the market and gives it a definite competitive advantage. Its conformation allows elements of different sizes to be joined, thanks above all to the practical method of the tongue-and-groove system: a solution that guarantees remarkable cost and time savings, and therefore greater efficiency when installing the trunking system.

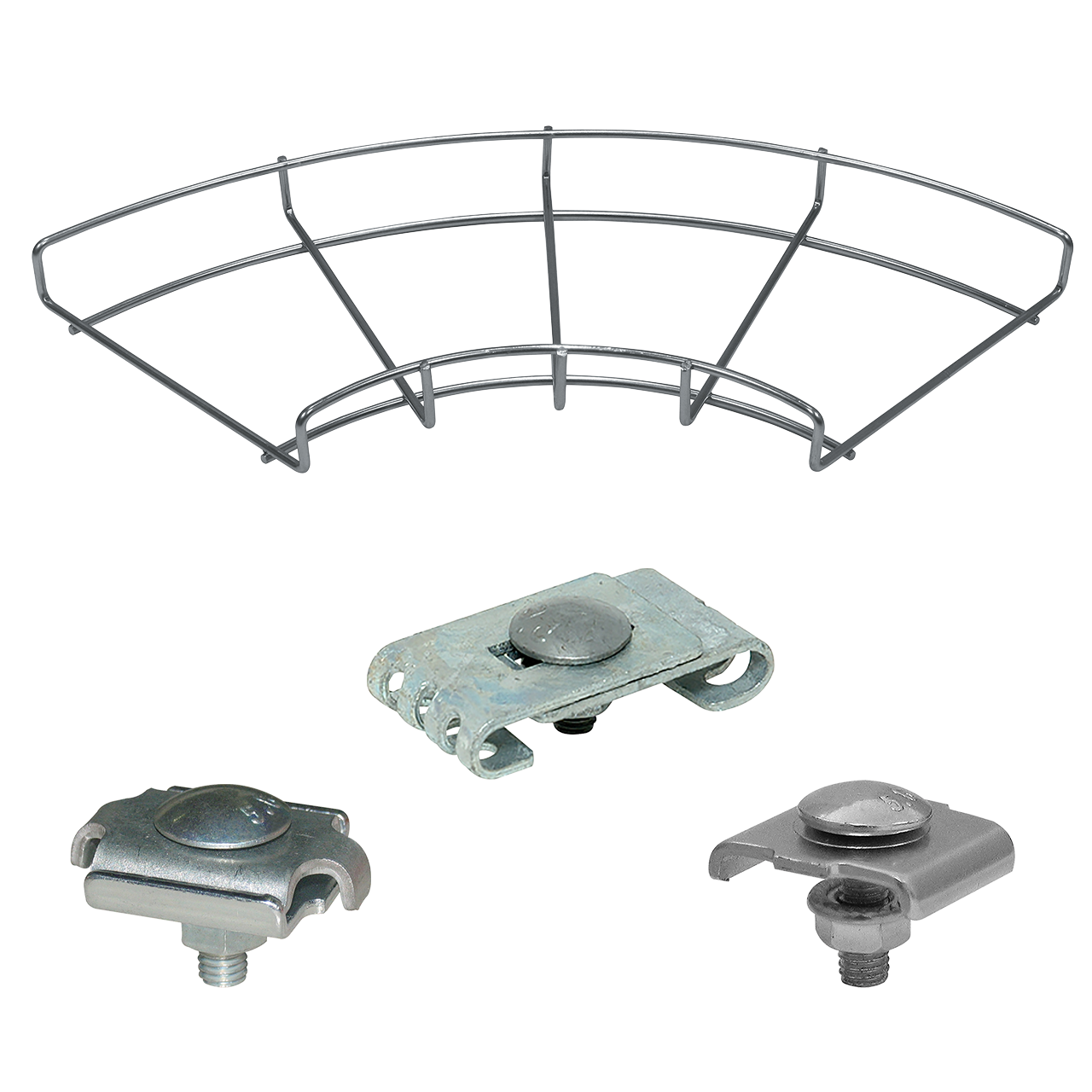

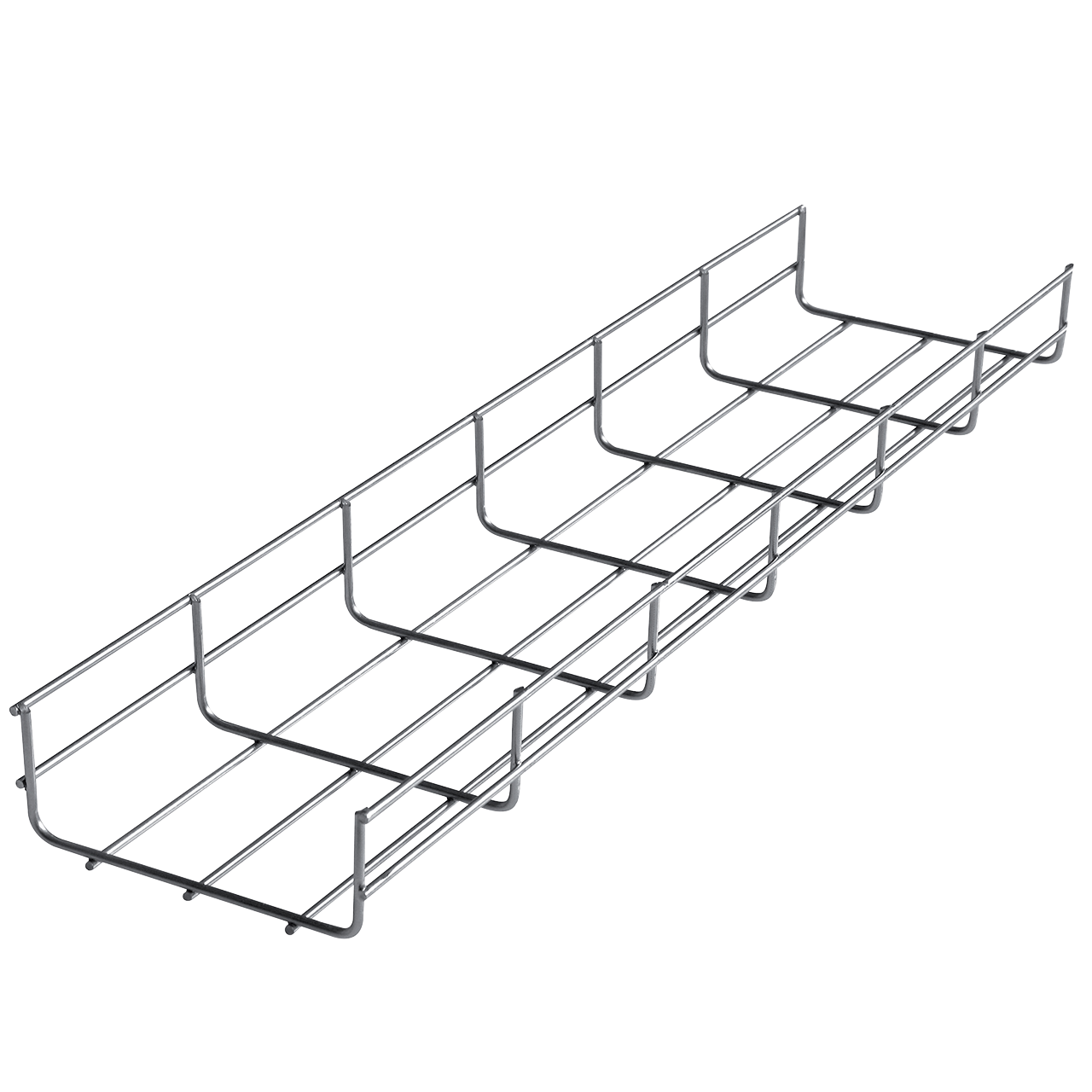

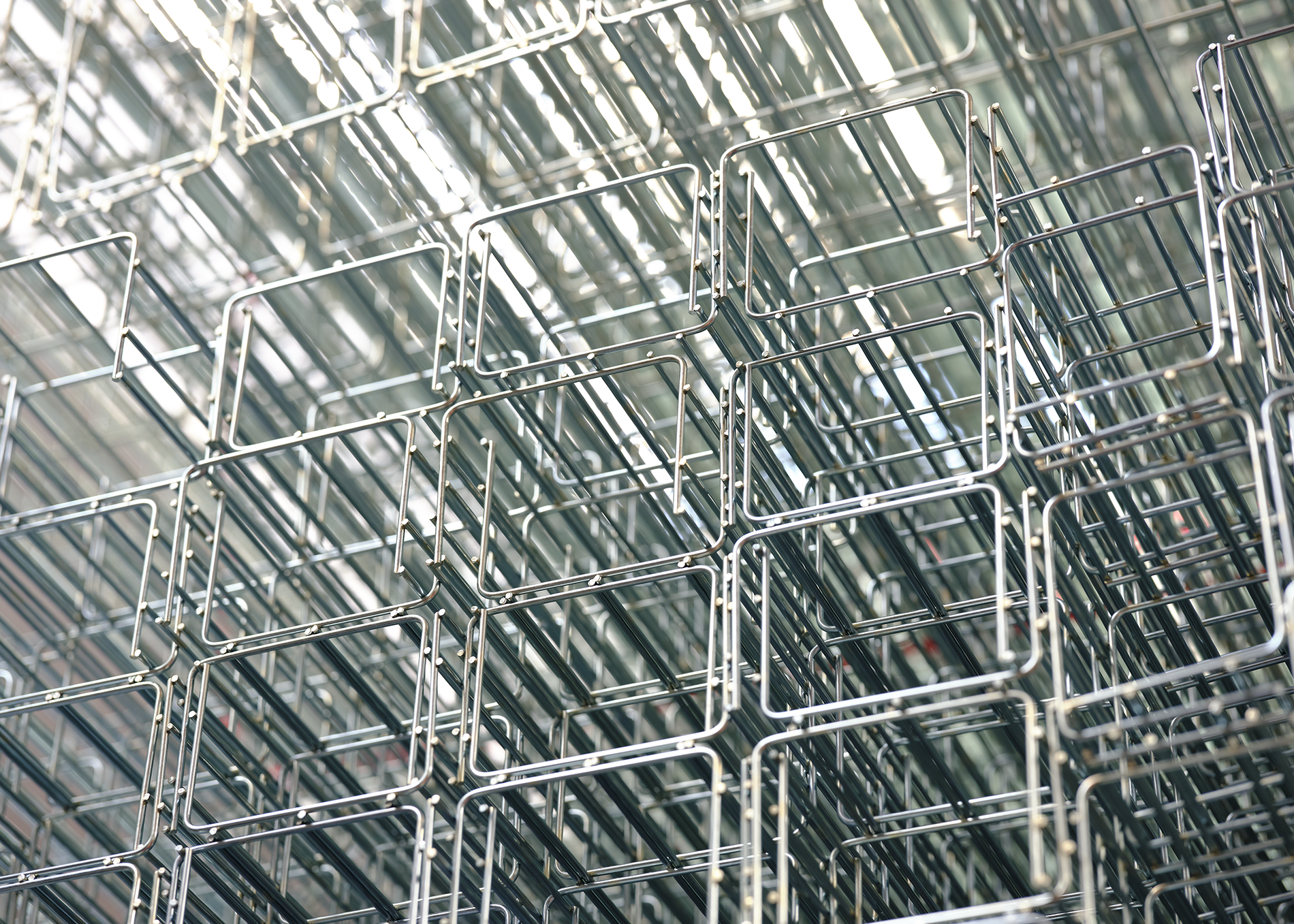

The S2 Line of mesh cable trays was conceived to create synergies with the other Sati Italia trunking systems: the Line S5 and the Line S3. The S2 Line is a complete system that utilises some products, such as covers and brackets, already present in the Sati Italia product range. This allows:

• the installer, to use products they already know;

• the wholesaler, to reduce stocks and, at the same time, make it easier to find the product.

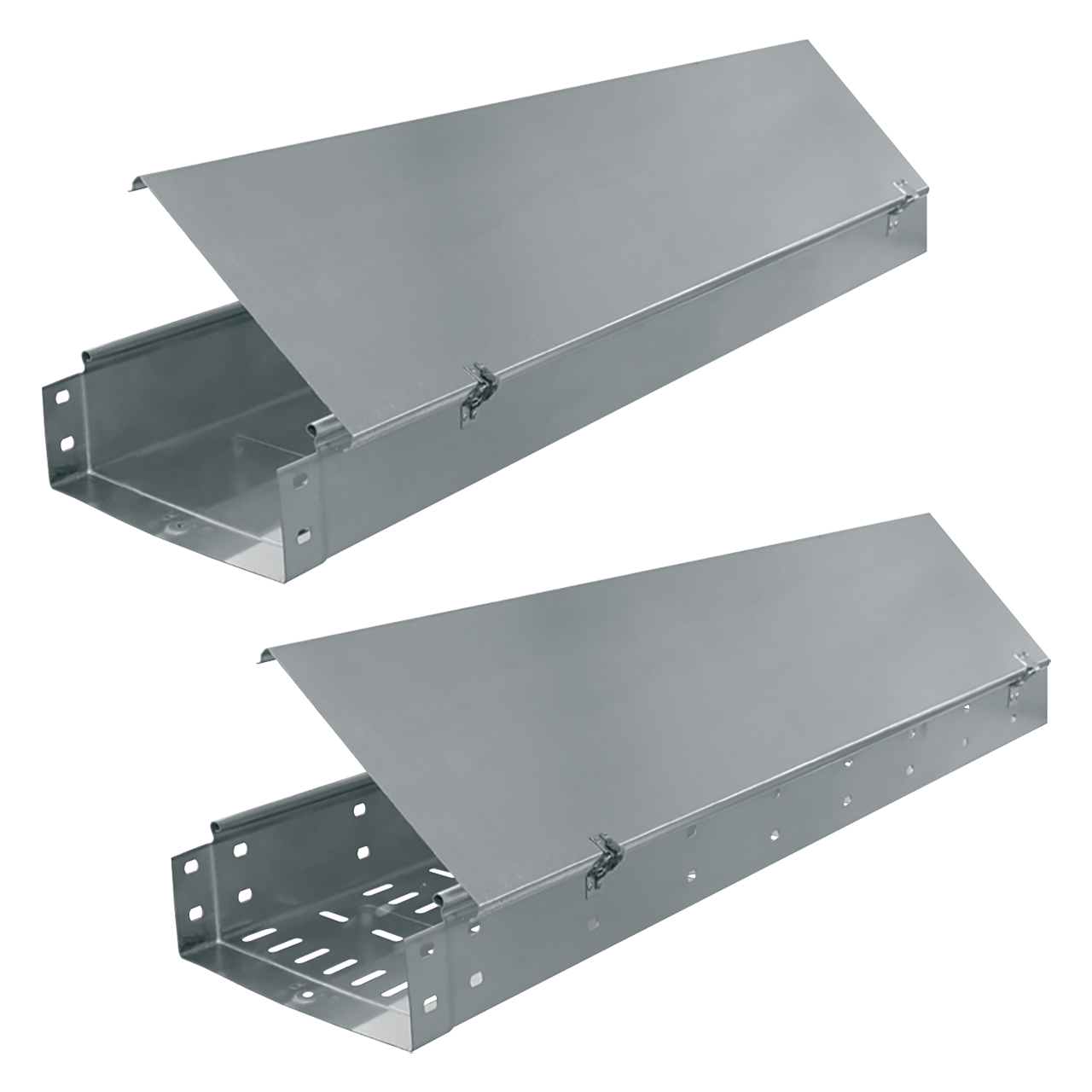

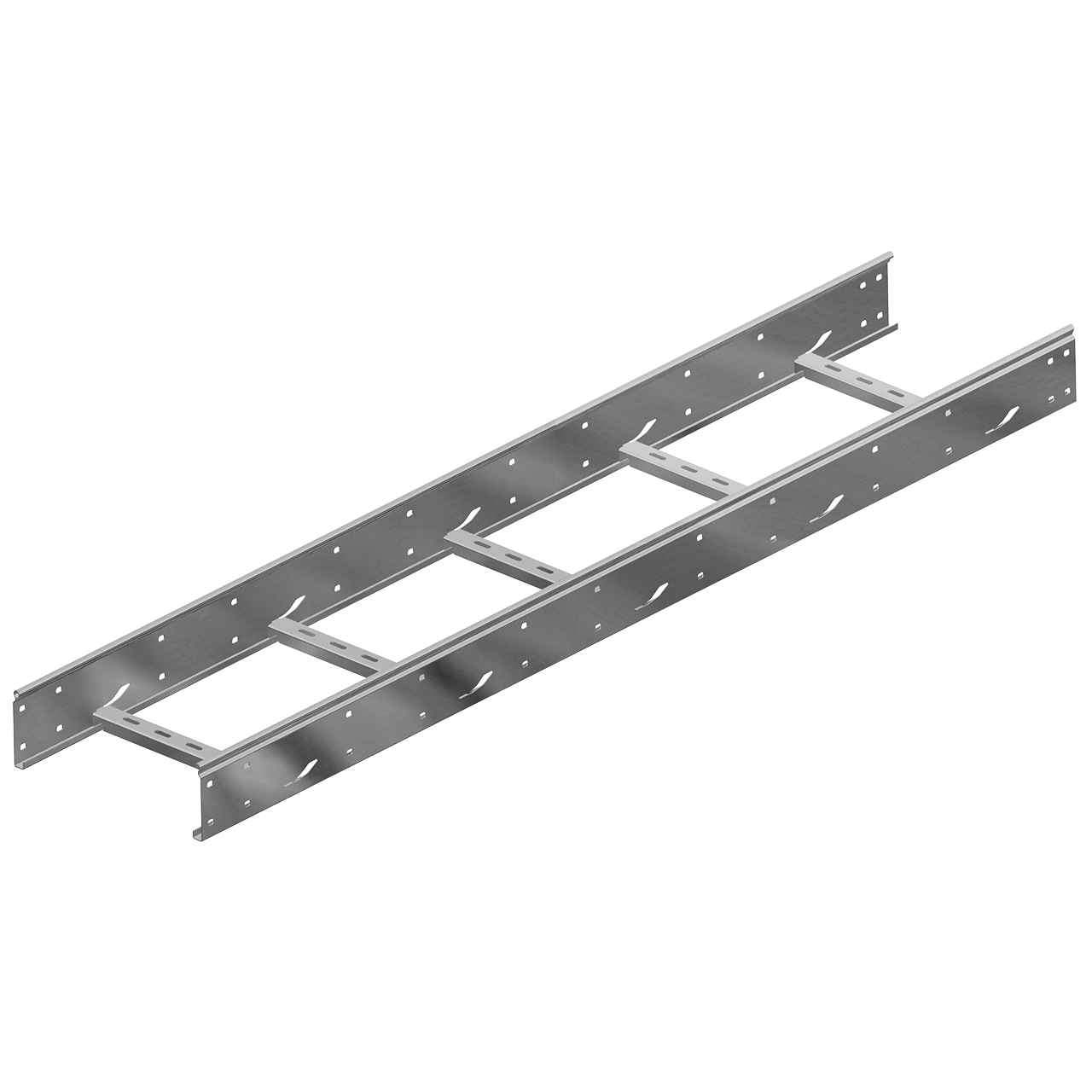

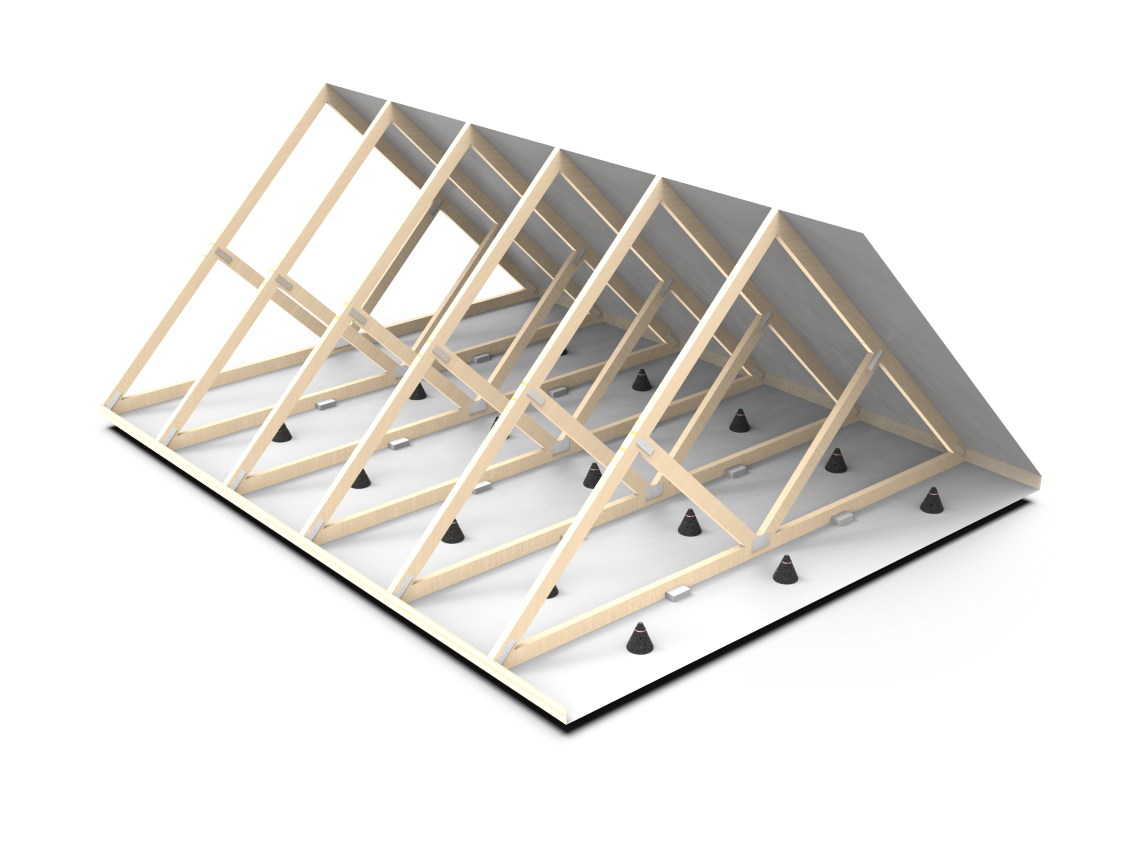

The main features of the S3 Line Cable Ladder System are:

- Snap Lid: thanks to its special ‘shaping’, the cover ‘snaps’ onto the tray. Even on vertical installations, the cover remains firmly fixed without the use of clips;

- Electrical continuity: In the case of a junction between two or more S3 trays with the use of the ‘Straight linear junction’, electrical continuity is guaranteed in accordance with IEC/EN 61537;

- Shims:

– Rails: 1.5 millimetres

– Thickness of crossbars: 1.2 millimetres - Distance of crossbars: the ‘pitch’ of the crossbars is 300 mm

- Bend radius: 300 mm (different radii on request)

- Rails/crossbar coupling system

The walkable trunking and cable tray system is designed for the protection and distribution of connections around any production facility and in areas subject to pedestrian crossings. Sati Italia products are manufactured with a thickness of 2 mm to ensure all the necessary support.

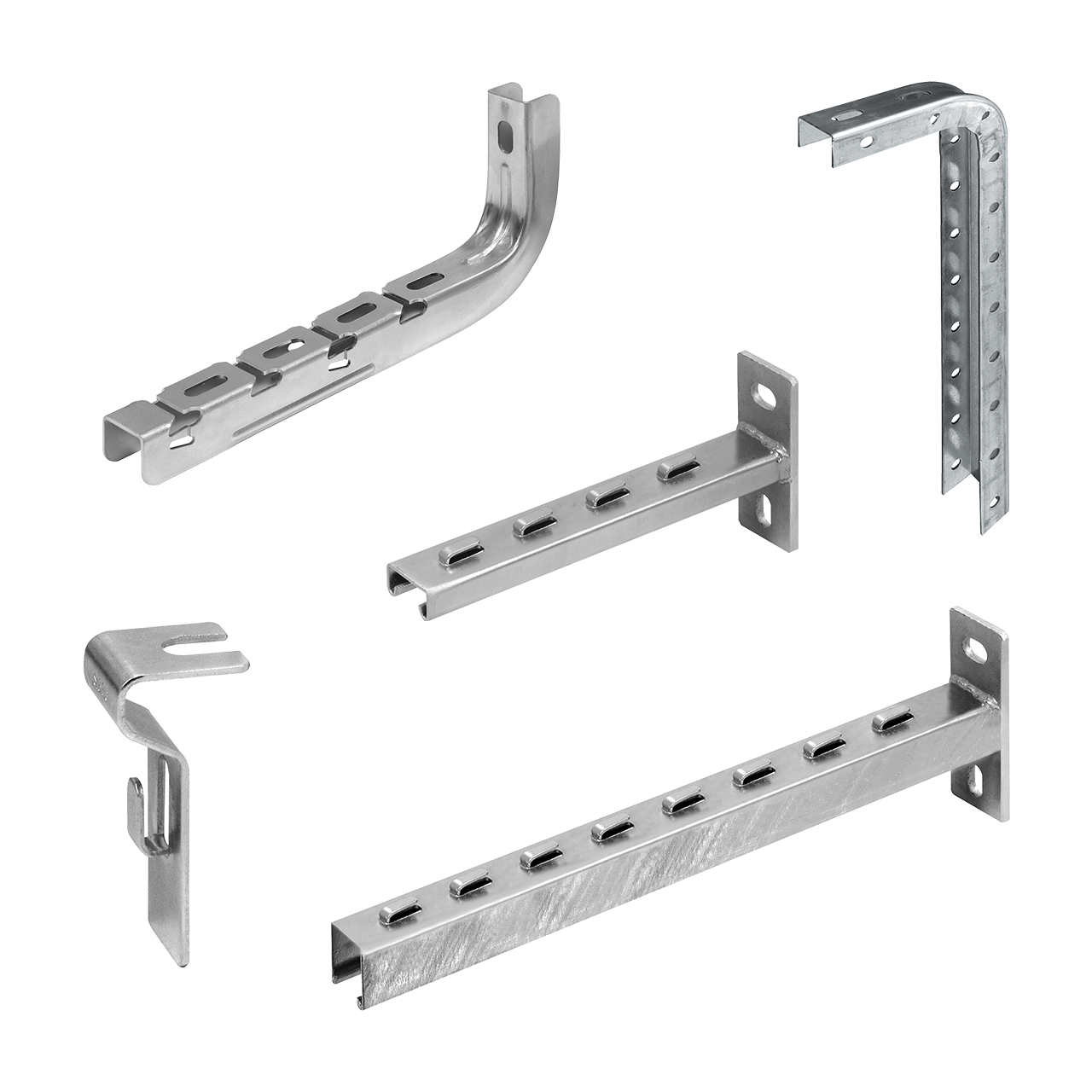

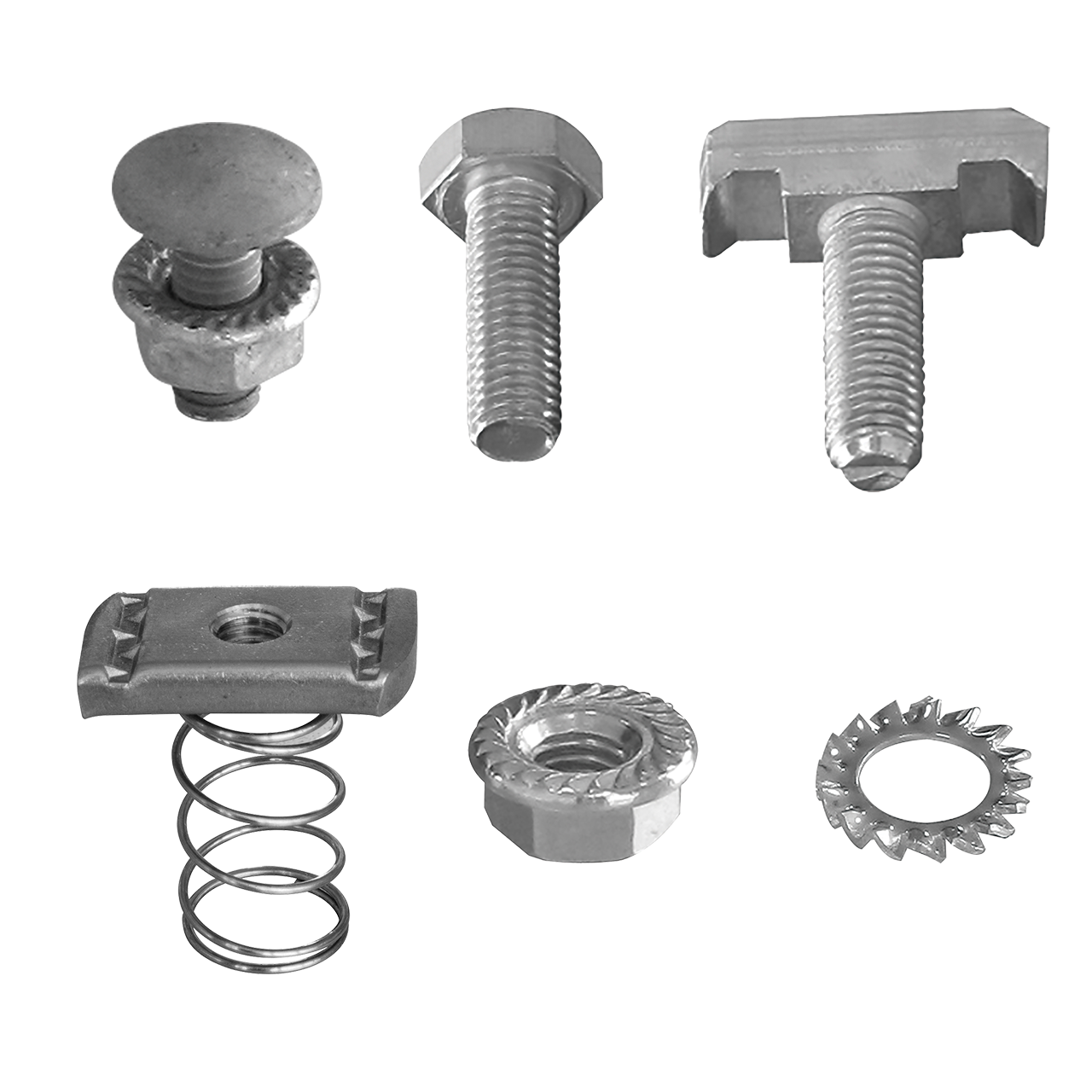

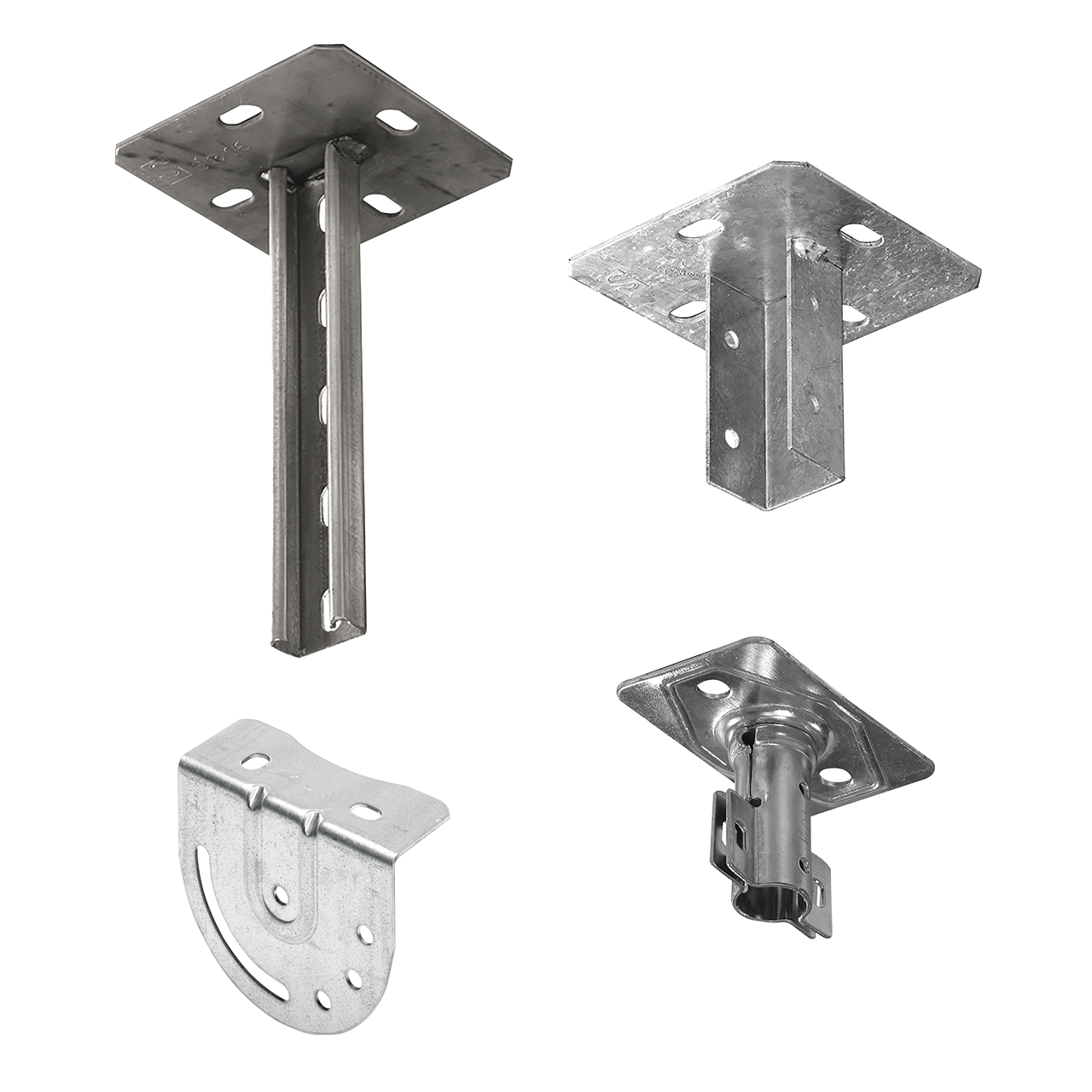

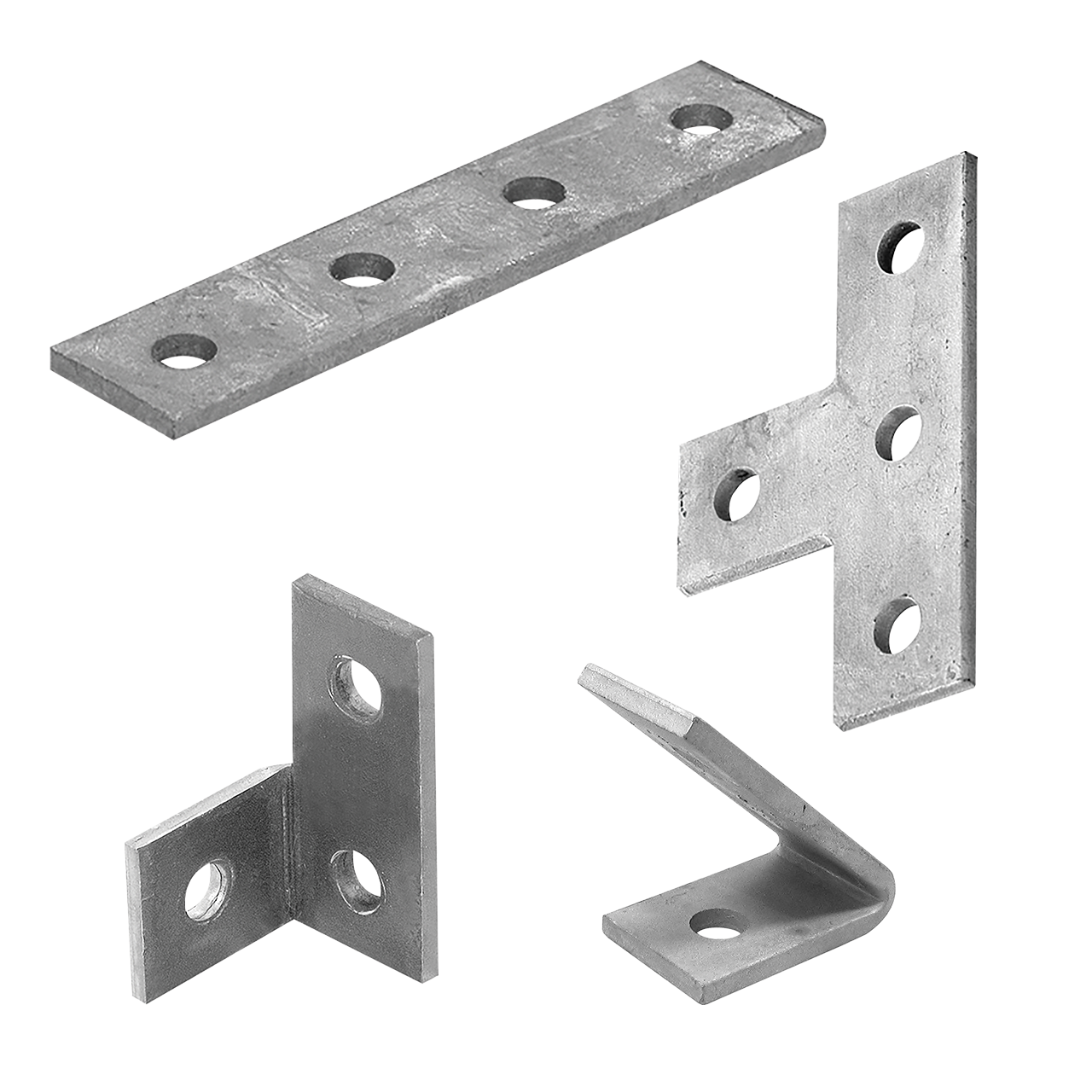

Brackets, profiles, joints, spacers and supports

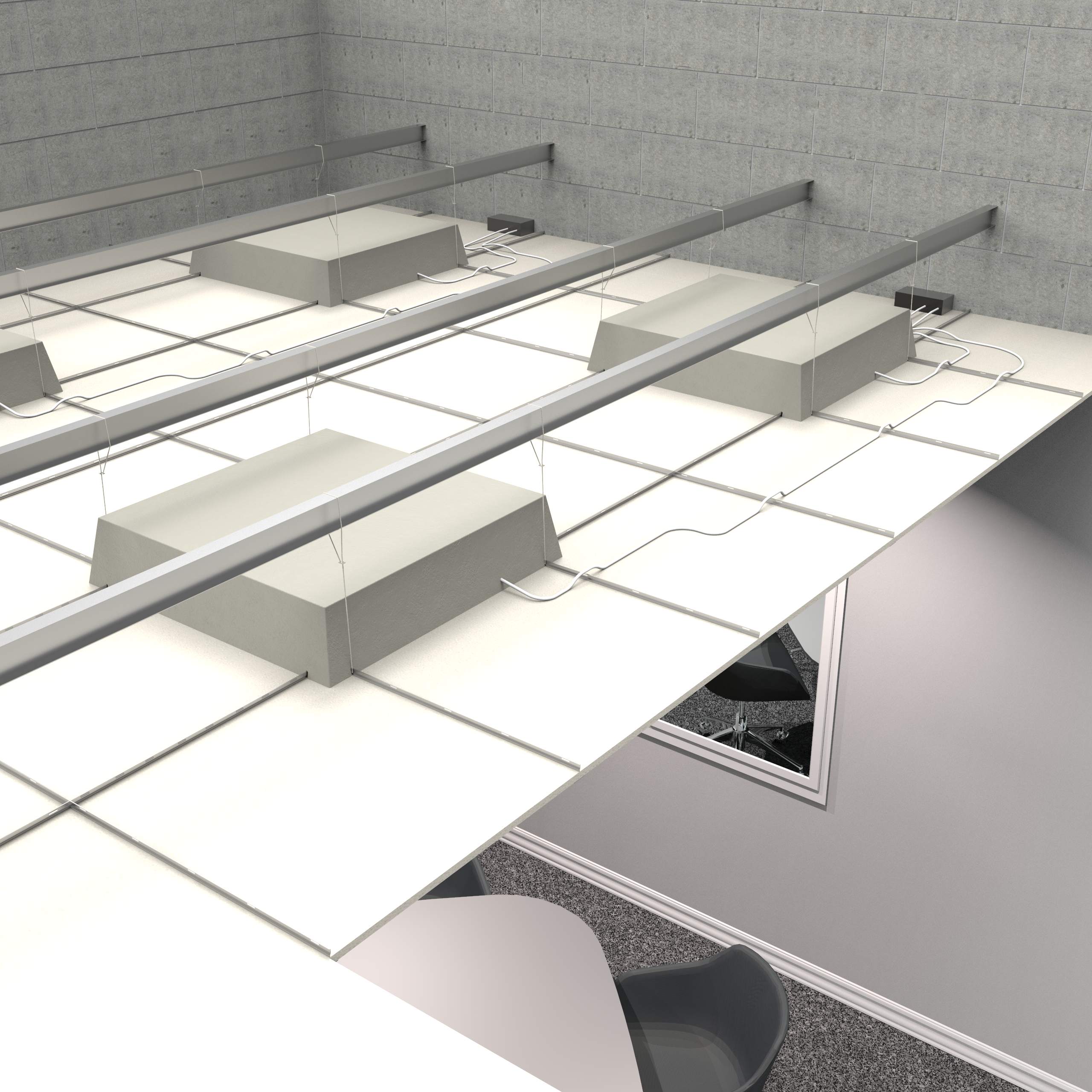

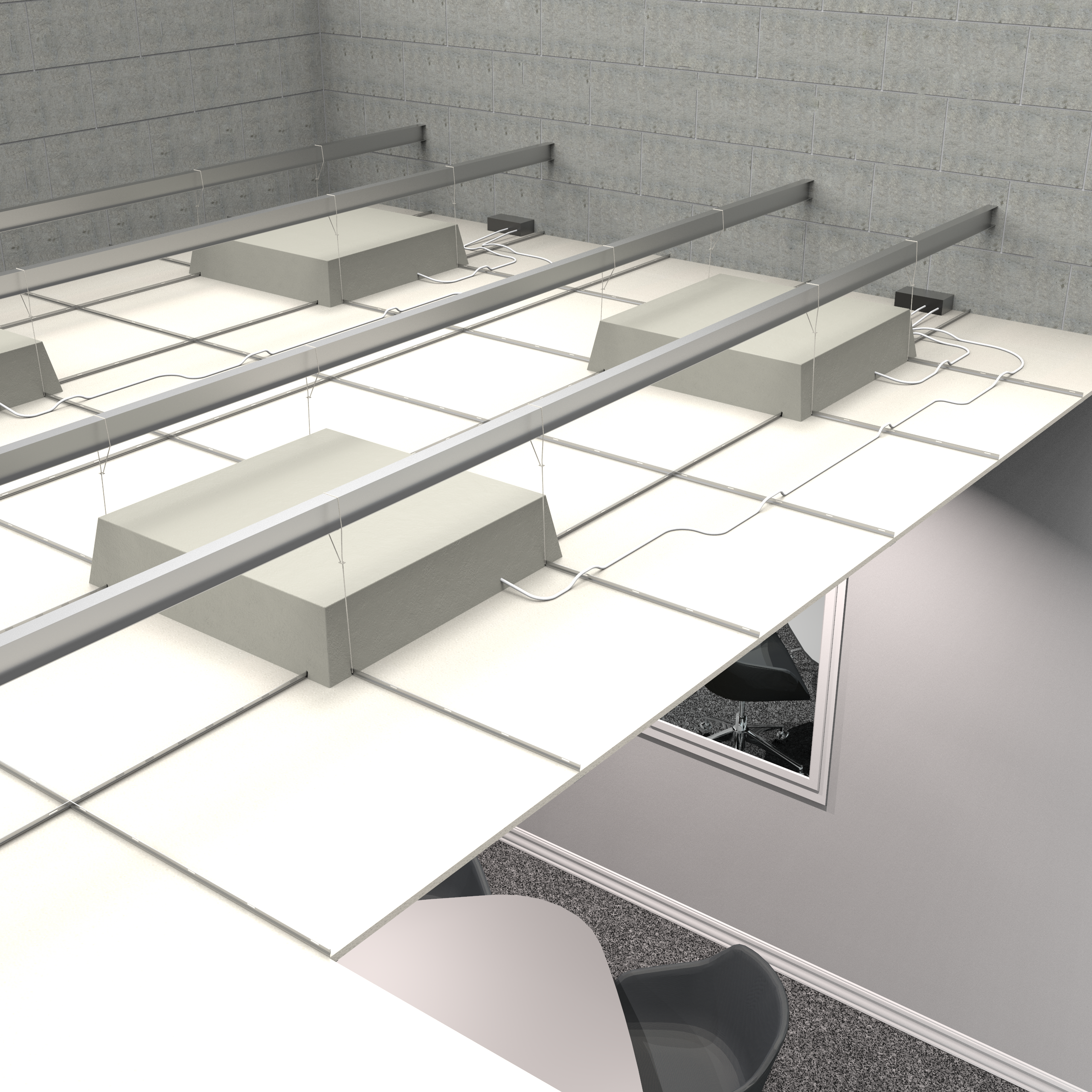

Sati Italia suspension systems are divided into:

- systems for medium loads;

- systems for heavy loads;

- mesh cable tray systems.

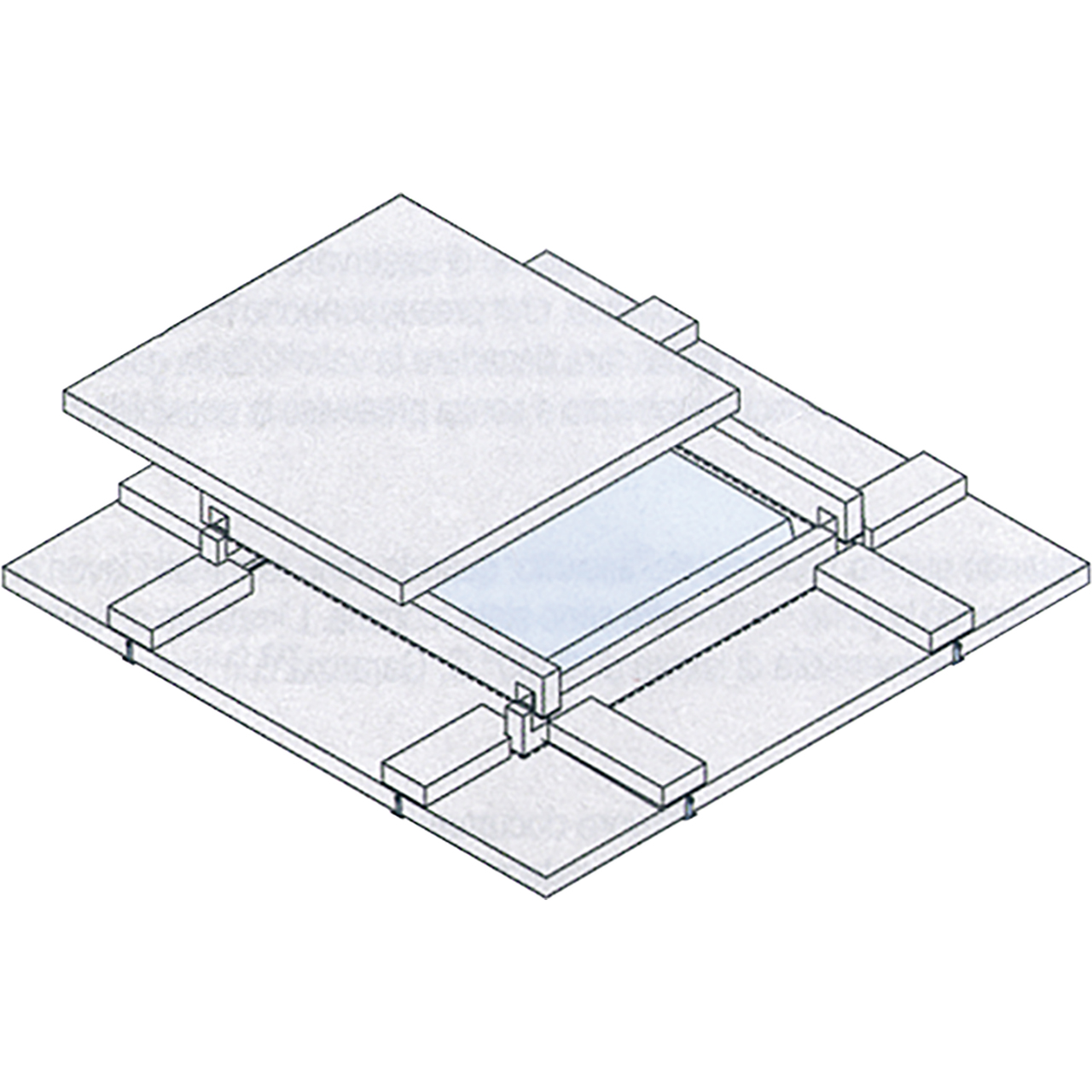

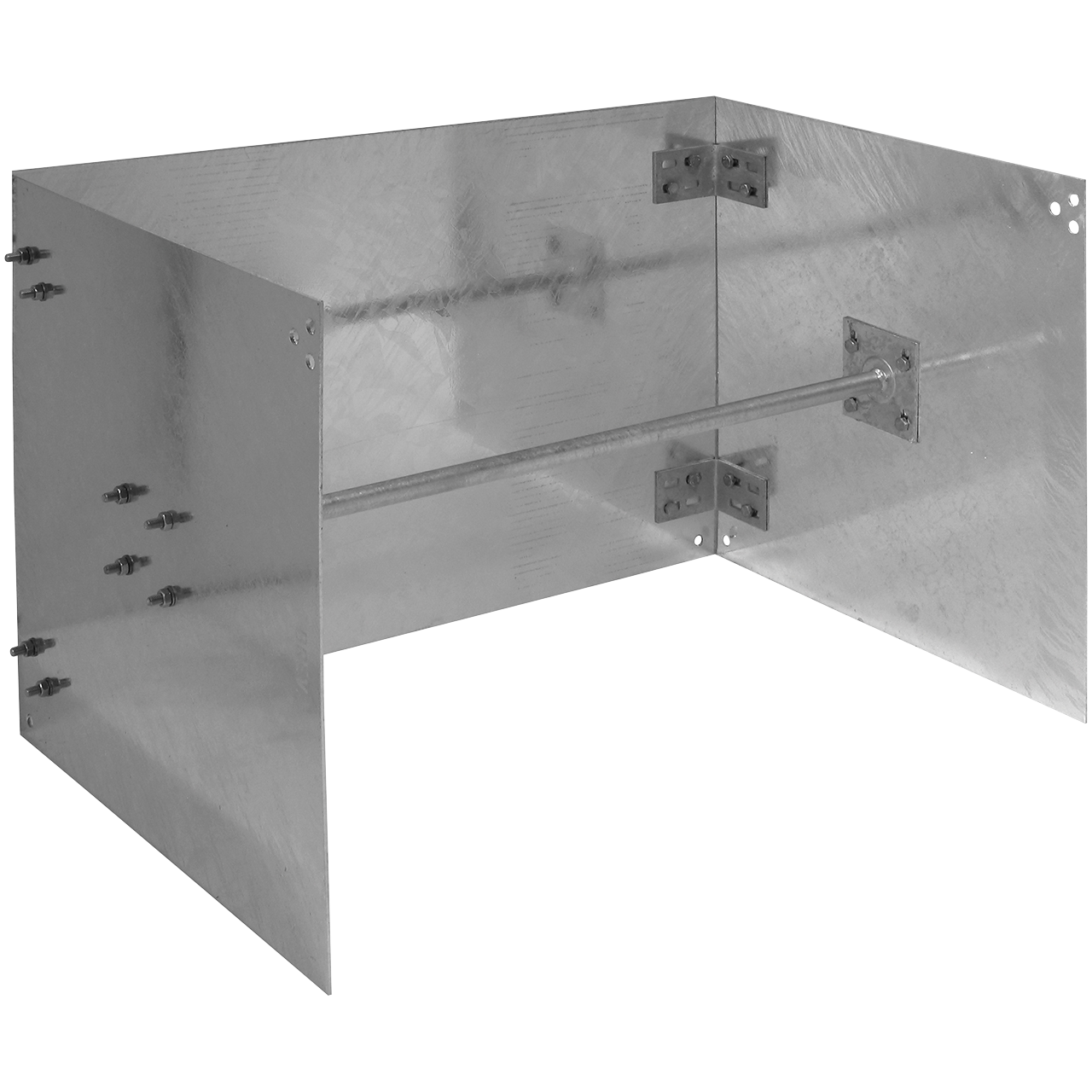

Modular structure system

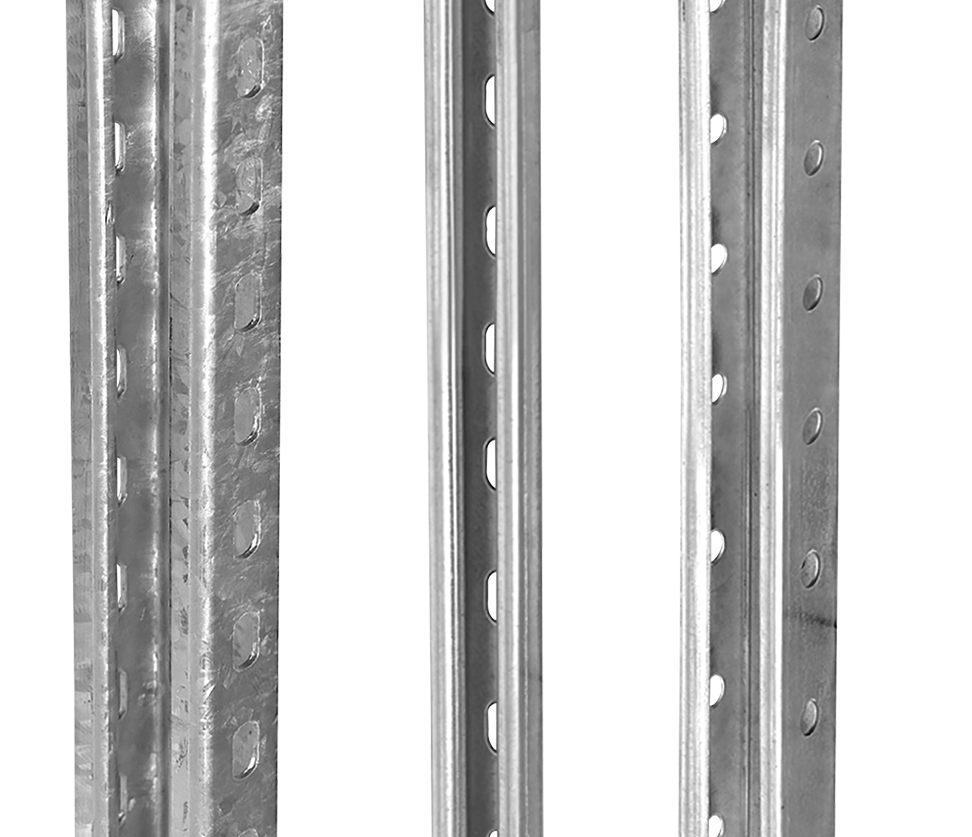

The Sati Speed Line is a practical, fast and cost-effective modular system for assembling any type of load-bearing structure, and is robust and adjustable. Profiles, connection and anchor plates, special attachments and other accessories can be used in any situation. A saw and a spanner are the only tools required for the assembly of any basic structure. The Sati Speed system is compatible with the hot-dip galvanized steel and Sendzimir suspension system accessories for our S2 Line and S5 Line trunking systems, and is particularly suitable for the installation of trays and cable trays, fluid or gas pipes, and air ducts in civil, tertiary and industrial installations.

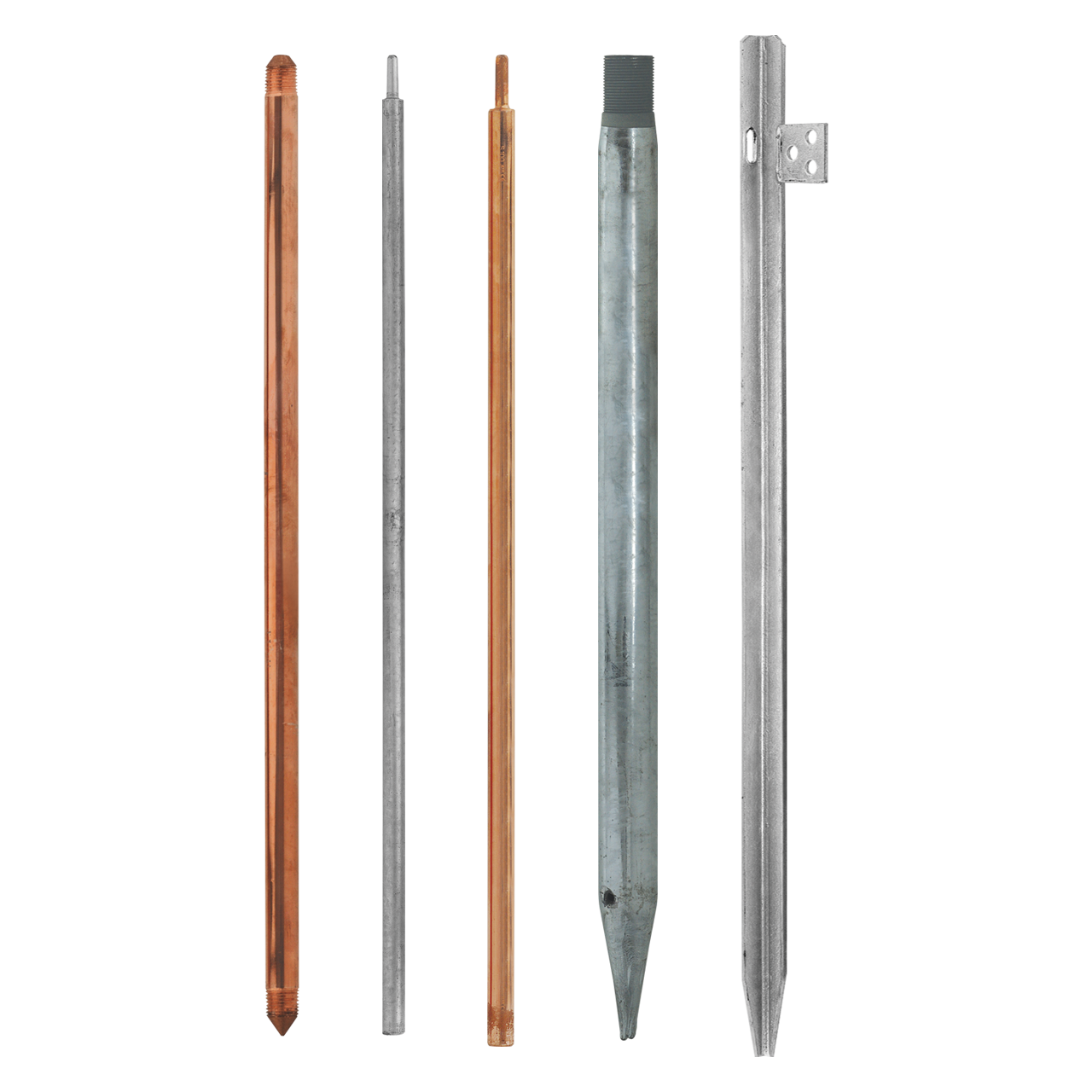

Sati Italia boasts an extensive catalogue dedicated to external LPS earthing and equipotential bonding systems suitable for realising projects in full compliance with current regulations. The catalogue is not intended to be a simple presentation of products, but is full of technical insights, practical examples of implementation and regulatory references. Among the various examples given, of particular interest are those on ‘Mesh Lightning Protection Systems’, for earth-termination systems, ‘TT Systems for residential and tertiary buildings’ and ‘TN Systems for industries, large shopping centres, hotels’, which simply and clearly provide the designer and installer with a complete model, relying on Sati Italia products.

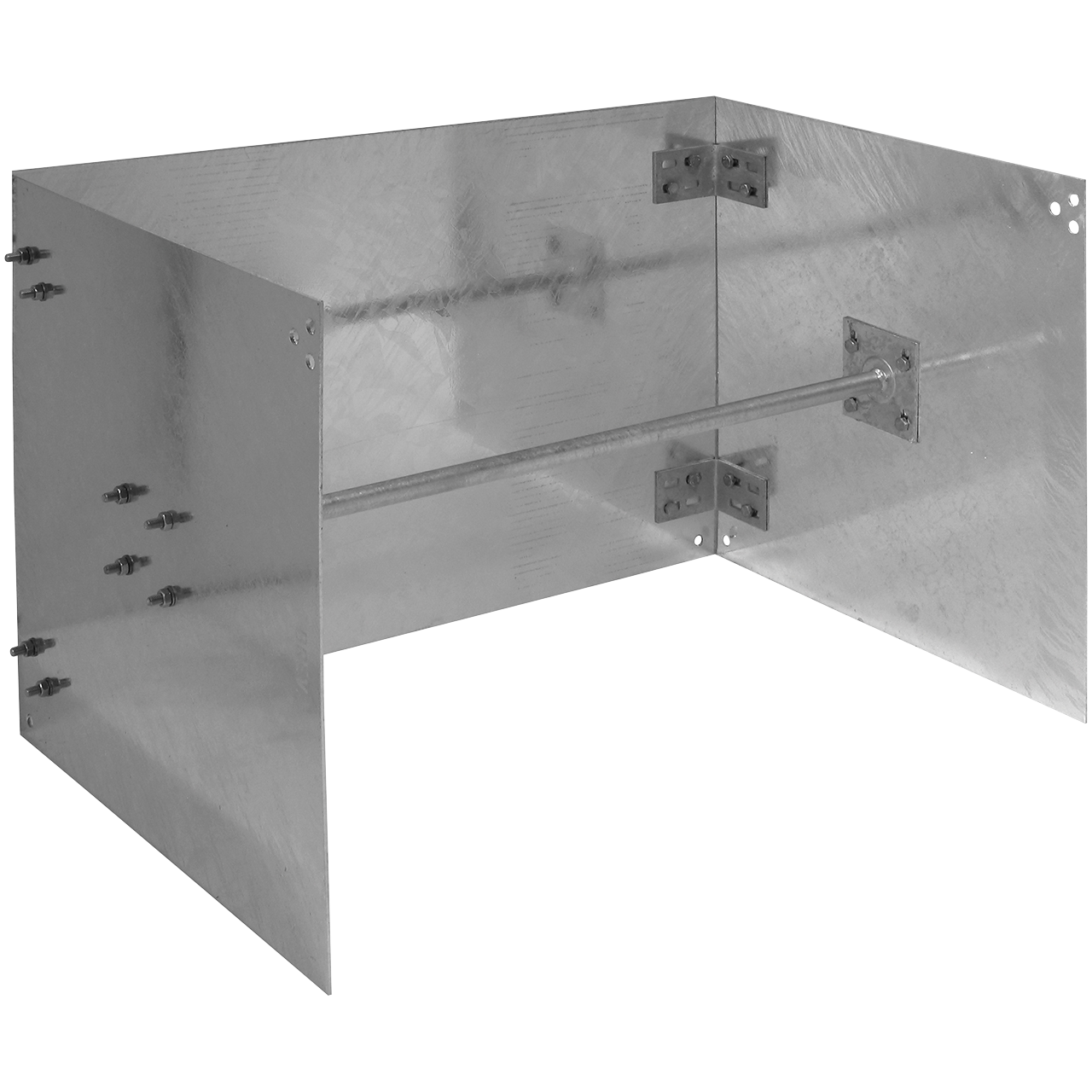

The PT4 modular earth electrode allows for any earth-termination system, meeting the requirements of Law 37/08 (formerly 46/90). The earth electrode, which is particularly suitable when the available surface area is limited (e.g. in historical town centres and apartment blocks), allows for earth-termination systems with particularly low values, thanks to its unlimited modularity and expandability. It can also be used to build earth-termination systems for TN systems in high resistivity terrain. The geometric configuration of the PT4 earth electrode offers an output comparable to 5 plates in parallel. Therefore, its effectiveness is equivalent to an average of 6 earth rods, 1.5 metres long, spaced 4 metres apart.

Ideal for earthing, lightning protection and equipotential bonding systems

There are several IEC (Comitato Elettrotecnico Italiano) Standards and Guides that regulate earthing systems, depending on whether these are low voltage, high voltage, or lightning protection systems.

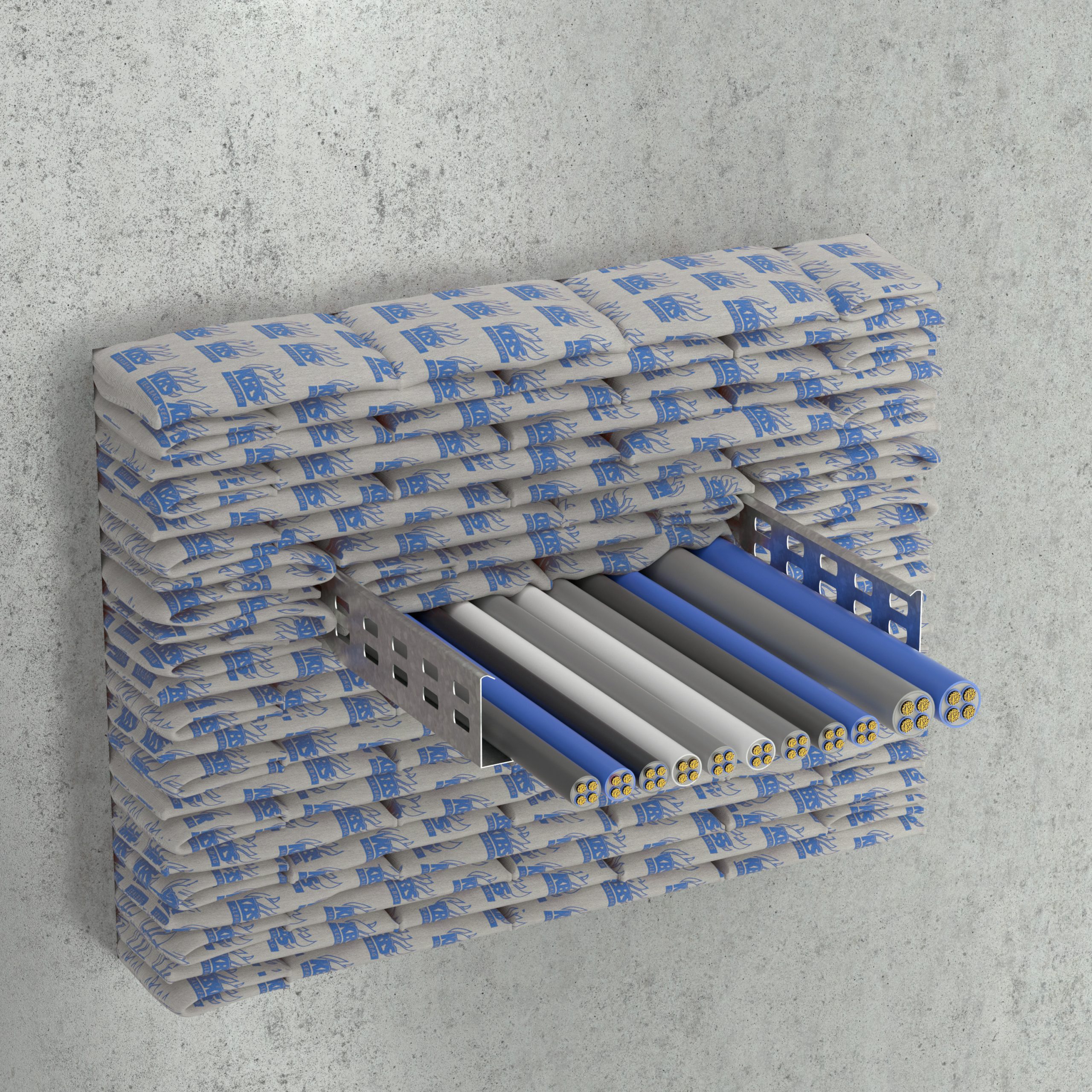

For passive fire protection

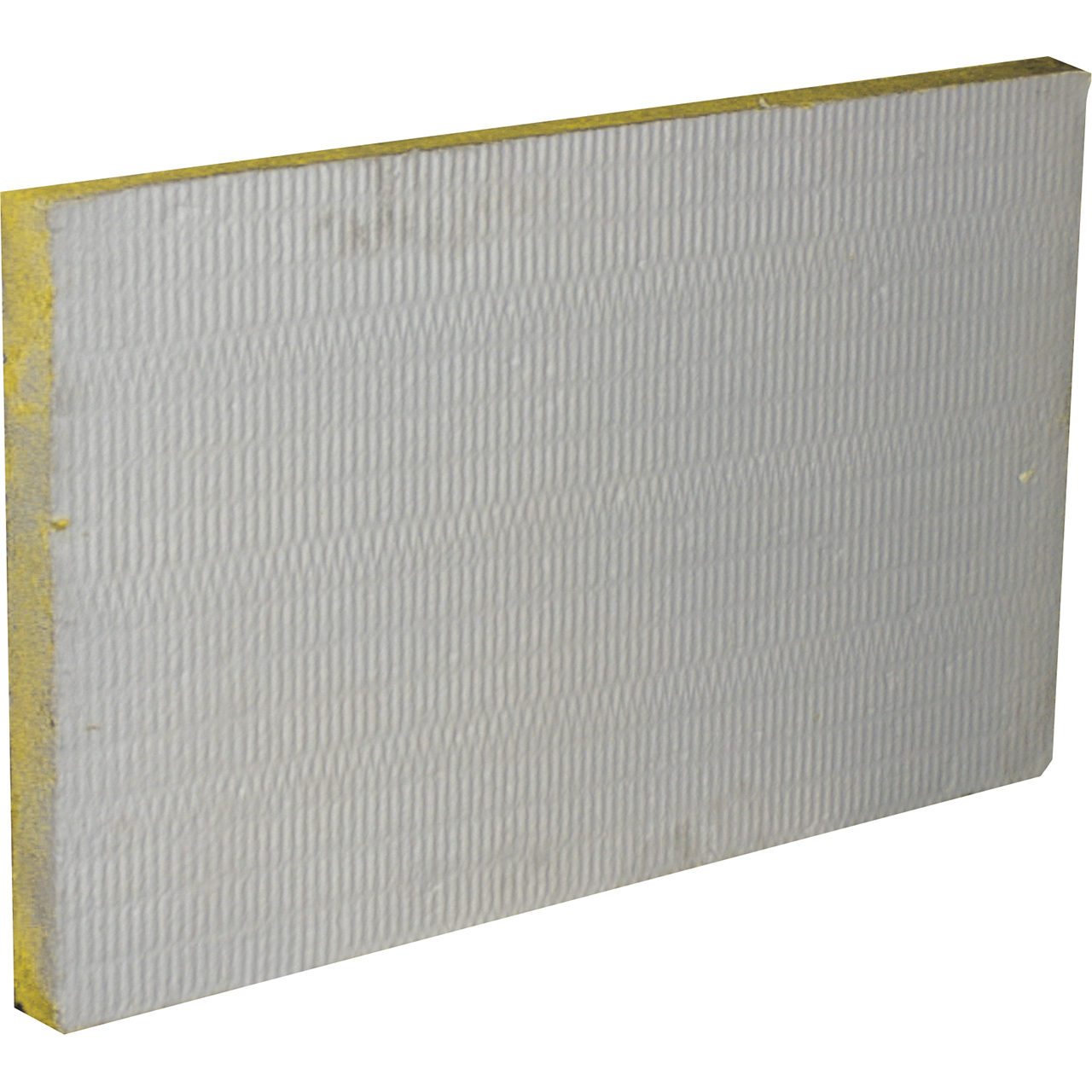

In the evaluation of the efficiency and safety parameters of electrical installations, a very important item is determined by the risk of fire caused, fuelled or propagated by the products that make up an electrical system. The simplest measure to prevent the spread of fire between different areas of the same building is compartmentalisation, whereby the areas at greatest risk of fire are cordoned off with fire-resistant walls, floors and Ceilings for a specific period of time.

For passive fire protection

Sati Italia provides its customers with a wide range of KBS systems.

FOR PASSIVE FIRE PROTECTION

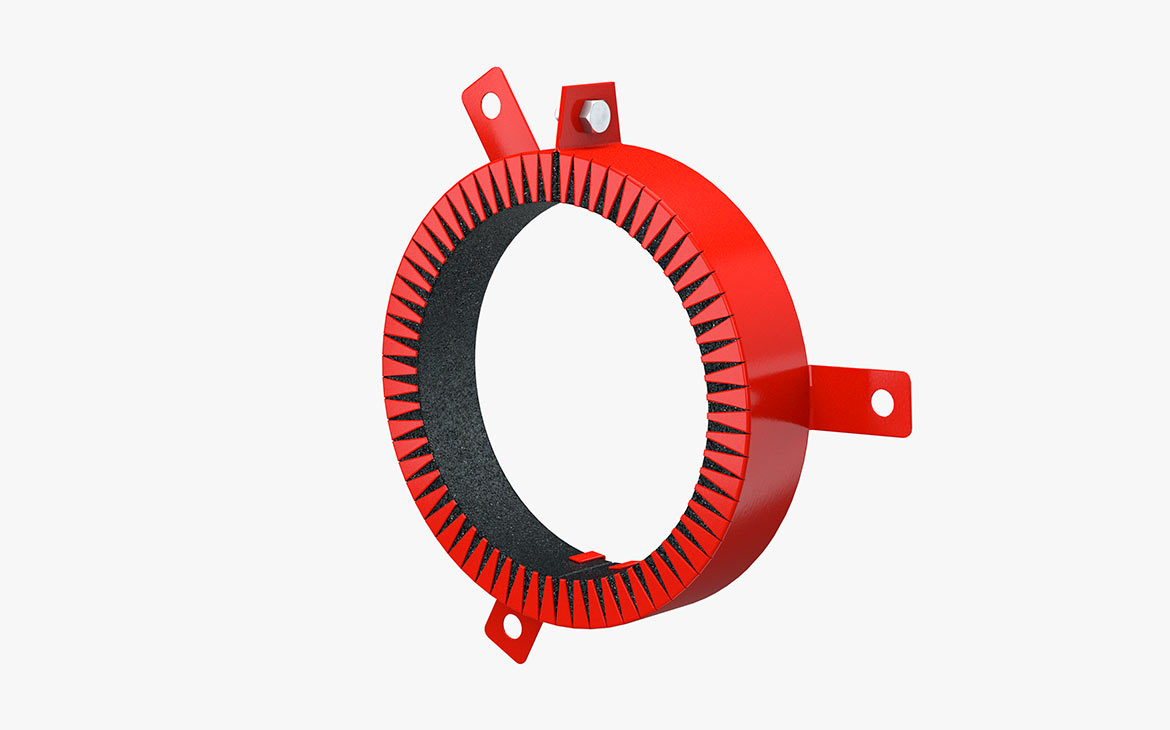

Sati Italia provides its customers with two types of downlighter covers, conical and domed, both certified UNI EN 1363-1 and UNI EN 1365-2.

FOR PASSIVE FIRE PROTECTION

Current regulations stipulate the need to reconstruct the REI continuity of the ceiling when crossed by a lighting fixture or acoustic diffuser. Compartmentalisation in the ceiling is respected by using REI-certified products.

In REI ceilings, luminaires must also be suitably protected against the danger of fire. Products certified for application, offer the necessary fire safety in compliance with fire prevention regulations.

Panel in intumescent material for fire protection of recessed electrical boxes and junction boxes. Fire protection of electrical boxes installed in lightweight plasterboard walls.

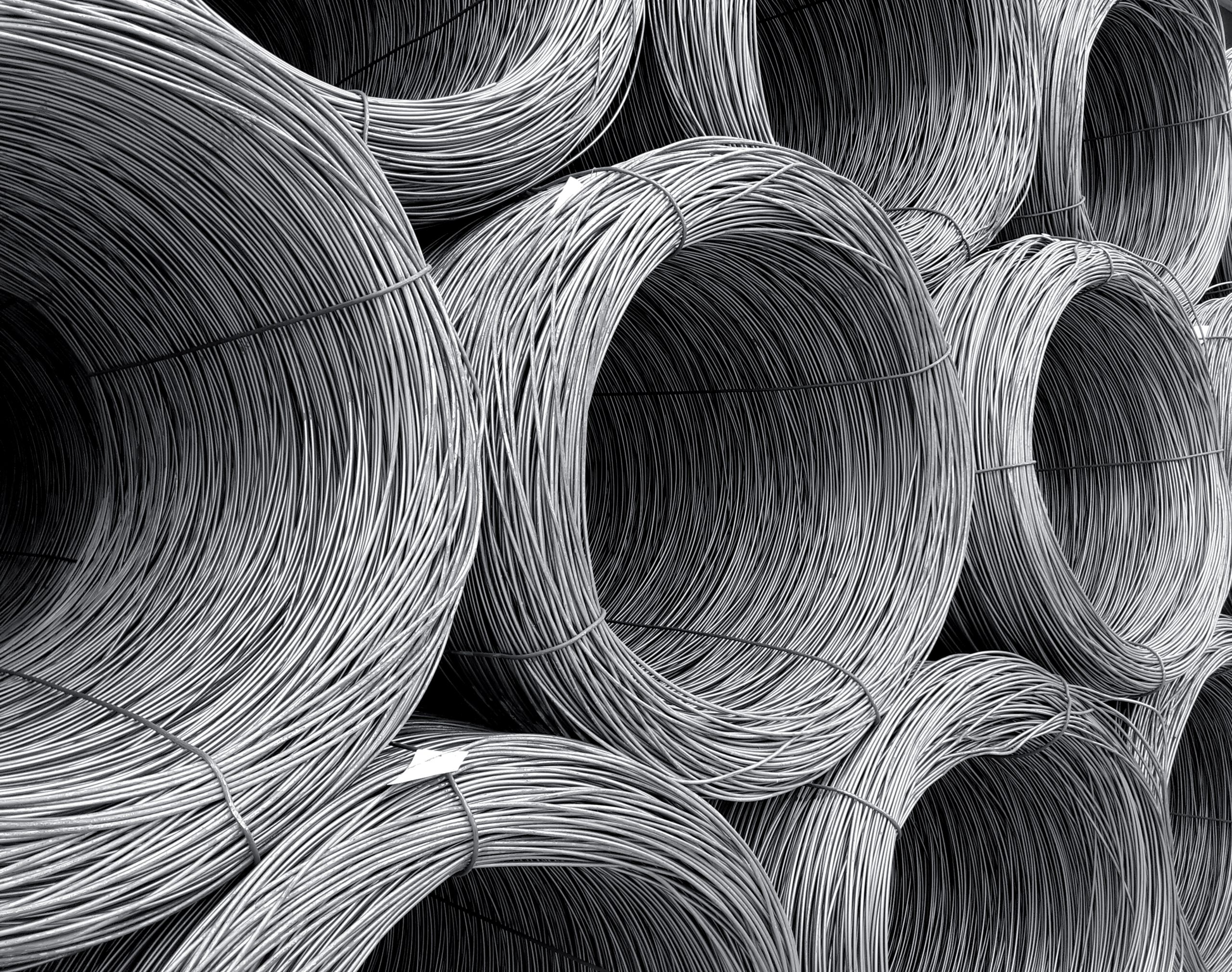

Alongside 100% Made in Italy production, Sati Italia offers its customers additional processing to guarantee excellent quality.

As a demonstration of its concrete and far-sighted commitment towards customers, the sector and the environment, in2004 the company installed a cutting-edge hot-dip galvanizing plant, an example of the Sati Italia excellence, at its plant in Latina.

Ensuring the best customer satisfaction in terms of product and service has always been at the heart of Sati Italia’s mission. The company is proud of the exclusivity within the sector of having a hot-dip galvanizing plant integrated in its production cycle since 2004. This is an important investment and, at the same time, a far-sighted choice, aimed at guaranteeing its customers maximum competitiveness with quality, durable, resistant and environmentally friendly products.

Sati Italia is distinguished by a rich offering of products and solutions related to the industrial electrical installation sector, with a core business corresponding to the wide range of metal trunking cable carrier systems. The company also specialises in the coating of these systems, thanks to a painting plant integrated in the production cycle, which allows them to be processed and applied with a type of painting known as ‘powder coating’. Powder coating is an innovative process, a safe and effective practice that replaces classic liquid coating.

Great reliability, long life

The long wine making process requires care and attention at every stage.

For more than 20 years, we have supported winegrowers with our experience in the production of high-quality steel vineyard posts, which are characterised by their high stability and ease of installation, guaranteeing a long product life.

Our industrial automation solutions are designed to optimise production processes, increase efficiency and reduce operating costs. Discover our tray systems, walkable trunking systems and cable carrier solutions, suspension systems and the Sati Speed Line.

Sati Italia stands out on the industrial electrical scene by offering solutions for the installation sector. Our tray, walkable trunking and cable carrier systems, suspension systems and the Sati Speed Line represent a comprehensive and reliable product range, suitable for every need.

Industrial safety is our priority. We offer a complete range of products that comply with the latest standards: earthing systems, lightning protection systems, earth plates and earth rods, fire barriers, protection systems for electrical junction boxes and solutions for passive fire protection.